Smart Configure Price Quote (CPQ)

Drive sales intelligence and acceleration in your business with CPQ software

Transform your selling motions with the solution that delivers value from quote-to-cash and beyond.

Omnichannel, data-driven selling – the experience customers demand

PROS Smart Configure, Price, Quote (CPQ) empowers sales organizations to deliver value from the moment the quoting process begins, all the way through the entirety of the customer relationship.

Powered by AI and machine learning algorithms, PROS Smart Configure, Price, Quote offers an omnichannel selling experience backed by meaningful insights that fuel stronger sales execution and growth.

As a result, B2B companies can offer the most relevant and personalized offers in real-time, with fueling an insights engine to capture every available dollar.

Discover how CPQ improves key aspects of your selling practices

Accelerate your Sales Cycles and Increase Deal Size with Performance Quoting

Enable your sales teams to create and manage quotes for all selling scenarios with speed and precision. From spot to subscription orders, and sales agreement alike, PROS Smart Configure Price Quote seamlessly scales to support up to 10,000 line items without sacrificing speed or performance.

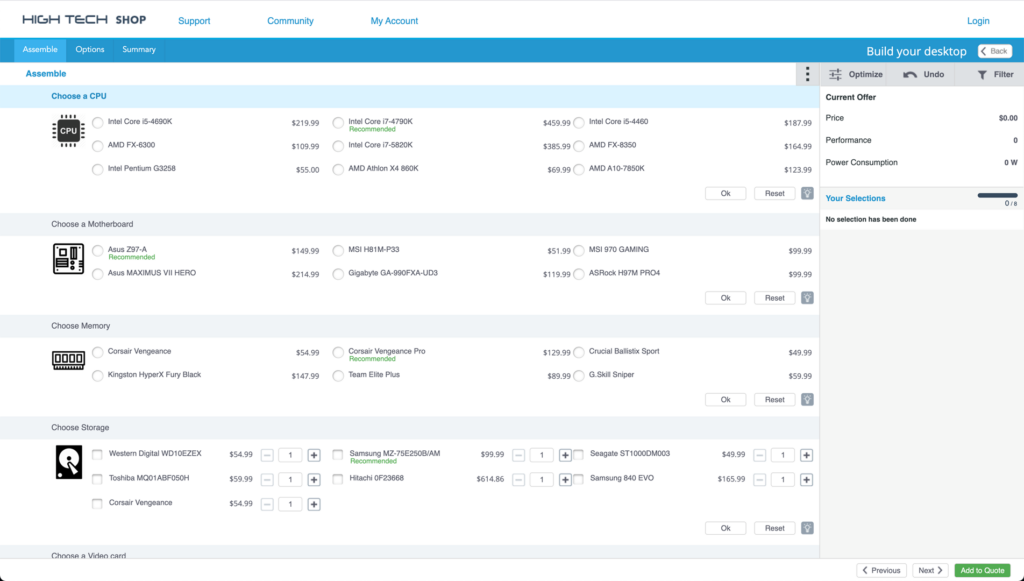

- Easily adapt the quoting process to business needs with step-by-step guided quoting workflows

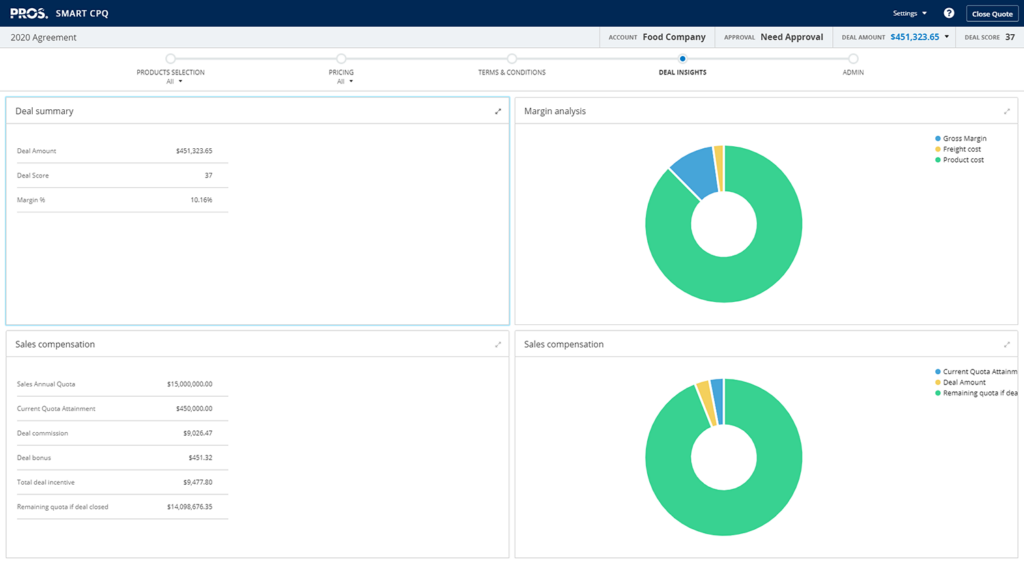

- Visualize profitability and analyze deal performance with integrated quote performance and waterfall charts

- Increase efficiency with a user interface that presents relevant and accurate information for reps to perform their tasks

- Leverage customer segmentation, buying patterns, market data, and a customer’s willingness-to-pay to deliver winning quotes

- Take advantage of data manipulation for large volume quotes

The Right Products. The Right Price. Every Time.

Guesswork, manual offer creation, and down-the-line quoting errors plague sales reps and put deals at risk.

By delivering the right offers – with accurate configurations – at prices your customers are willing to pay, PROS Smart Configure Price Quote gives your customers a superior experience and your business what it needs most – closed, profitable deals.

- Quickly find any product or service that’s available and appropriate for sale with a robust digital catalog

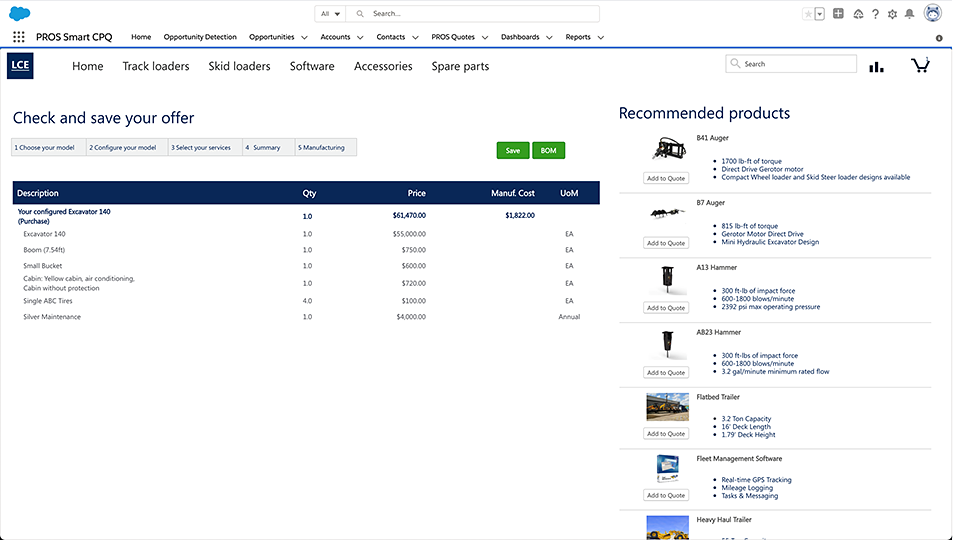

- Deliver personalized offers for every deal in record time with guided selling, faceted search, and AI-based cross sell recommendations

- Configure the most complex, engineer-to-order products or services without any errors thanks to an easy-to-use and powerful configuration tool

- Constraints-based logic eases the administration of creating and managing all your configuration logic

- Reuse your configuration models in any experience, including eCommerce

Identify Opportunities with Existing Customers

Presenting fresh opportunities to your current customers not only helps deliver value but lift your profits by 25% or more.

Powered by AI and machine learning, PROS Smart Configure Price Quote puts a magnifying glass in your reps hands — empowering them with tools to increase customer loyalty and wallet share simultaneously.

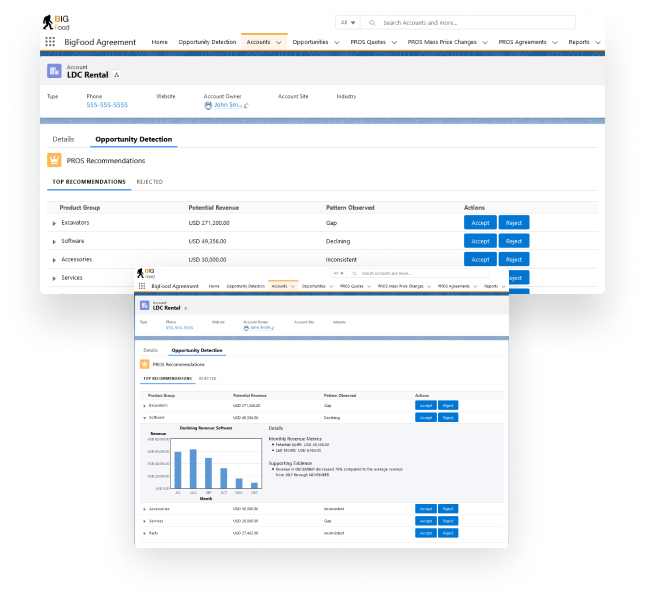

- Compare similar account portfolios to see buying inconsistencies

- Identify white space for additional sales opportunities and quantify the revenue potential

- Find and mitigate declining patterns that indicate a customer shifting to another vendor

- Automate opportunity creation with seamless integrations into the market’s leading CRM platforms

How does an Integrated Selling Solution Garner Trust at the C-Level?

With an understanding of hidden trends within market, business, and customer data, you’re equipped to respond to competitive movements at every point in the customer journey — helping to deliver value to the customer while also fueling your revenue engine.

From a best-in-class quoting system that helps you cut discounting and long turnaround times, to a more seamless sales agreement process, efficiency and accuracy replace manual systems that once left room for error and customer frustration.

How PROS Science, AI and Machine Learning technology optimizes your selling motions

Editions

Great for businesses looking to simplify the selling of more complex products, creating bills of materials, and managing the lifecycle of sales purchase agreements.

Smart Configure Price Quote is part of the PROS Platform,

a unified SaaS solution at the heart of driving transformative selling experiences.

Businesses today rely on the PROS Platform to deliver personalized offer recommendations to their buyers, through all possible sales channels, resulting in greater sales at higher margins.

Learn how you can make every buying experience more personalized and every transaction more profitable.

Looking for the PROS Platform for Airlines? See it here